Cooling

systems

optimise

Innovative Cooling System

Decentralized energy supply for medium-sized industrial applications by innovative power-heat-coldness-linkage

Objective of this project is the development and optimization of a cooling-system for refrigerating capacities up to 100 kW, based on a combination of power-heat-linkage and absorption technology. The system targets on providing coldness as well as electric power in an eco-sensitive and financially attractive way. This technology is nearly universally usable as in most industrial areas there is both a need of energy supply and coldness.

Due to the carbon emission problem as well as raising energy prices, high strain is applied on manufacturing branches, especially on those ones with extensive demands on energy. Aluminium- (à anodizing) and plastics (àinjection molding process) industries are representatives of industries which need energy, heat and coldness. Due to so far unsolved conduction problems, the decentralized energy supply will become more important in the medium term. The idea of the project is a combination of a diesel/gas engine combined with a generator and an absorption chiller (cold level -10°C, refrigerating capacity <100 kW) with computerised process control. Further tasks are the development of a modified use of heat of gas exhaust in order to realize temperatures on a range of 95°C to max. 120°C for the drift bolt, as well as the utilization of the excess heat from the power generation. Finally the entire system should be as adjustable as possible so that it can be used for many applications and it can be fitted to the required purpose with low effort.

Previous results

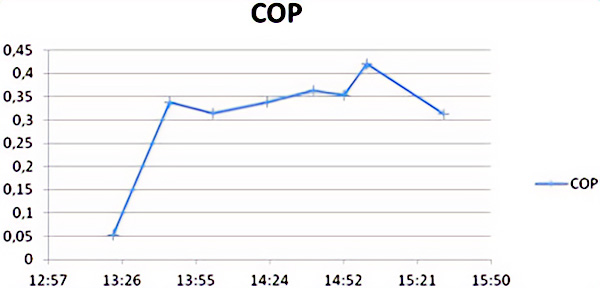

The objective of reaching a coldness-level of up to -10°C is just reached with containment with the current system. Reaching of the temperatures depends on the load. With a favourable load the current system achieves a maximum of -8°C. The desired cooling capacity of 50 to 100 kW has been achieved to some extent in lower power ranges, but not in continuous use. Using a low-temperature absorption unit, the desired expeller temperatures of 95°C up to 120°C max., become unnecessary. For a power of 50 kW the new facility requires drift bolt temperatures of only 85°C - 95°C, which is a vast improvement. These temperatures can be nearly reached. The revision of the current heat exchanger is necessary for this. The target COP (coefficient of performance) of 0.7 cannot be achieved. A COP of 0.4 had been realized.

Savings of fuel and this CO2 of 10% can be realized. The use of excess heat from power generation for heating and drying purposes can be realized by the use of heat exchangers, which include the warmth of the engine cooling water and the exhaust in the entire system. The system is modular so that it can be adapted to various applications.

The realized demonstrator shows that an innovative power-heat-coldness-linkage for decentralized environmentally friendly and economical provision of refrigeration, electricity and heat for industrial applications is available. Particularly in the refrigeration pays sharing the exhaust energy and the engine-cooling water energy. Through further optimization the residual heat of the exhaust stream to heat water or air-conditioning or drying can be used. Further steps up to the production stage and commercialization of this technology are improvements, such as on the heat exchanger, as well as a reduction of the system to the size of a container, equipped with a modern and economic engine generator with an integrated refrigeration system.

Verlauf des COP (Coefficient of Performance) im Testlauf

Thanks

We thank the State of Nordrhein Westfalen, which promoted the program "Rational utilization and use of inexhaustible energy sources - REN" in the context of the State Initiative on Future Energies NRW, in which we could bring in our research project "Innovative cooling system for industrial applications." Without this support the project for a medium sized company would not have been feasible.

Furthermore, we thank the Project Management Agency Research Centre Jülich, especially Mr. Dipl.-Ing. Lothar Funk and his team for their outstanding support in technical and formal concerns. Last but not least, we thank the participants in the project, Prof. Dr. Ingo Romey and Dipl.-Phys. Dirk Caemmerer for their contributions to the project success. Special thanks to Dipl.-Ing. Robin Strehl and Mr. Peter Götz for their valuable help.

PENTAGAL

Chemie und Maschinenbau GmbH

Carolinenglückstraße 35

44793 Bochum / Germany

Phone: +49 234 / 52 32 37

Fax: +49 234 / 52 29 89