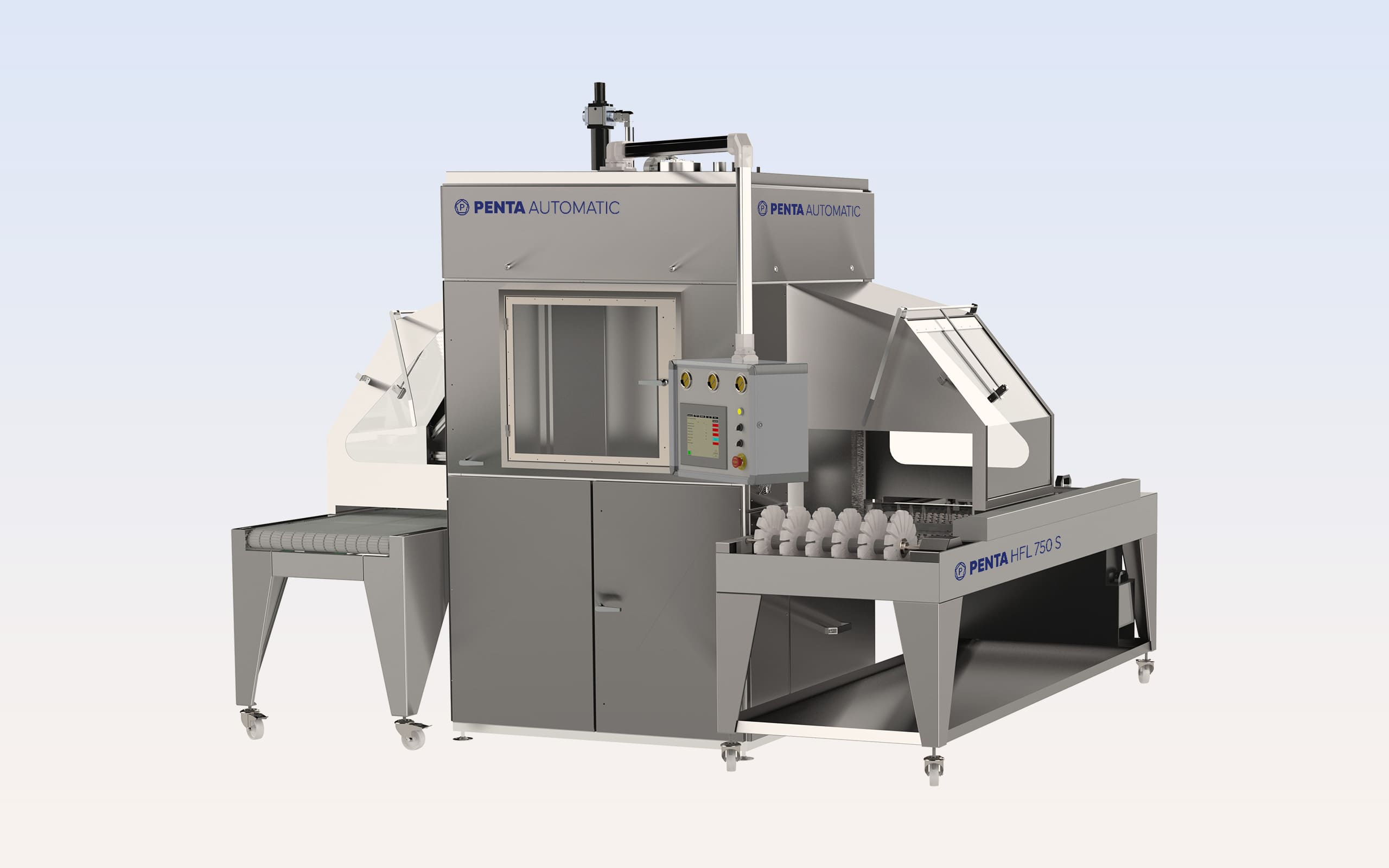

PENTA AUTOMATIC

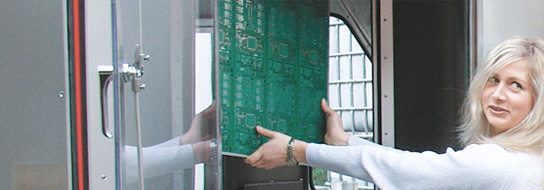

Vertical automatic Hot Air Leveling system

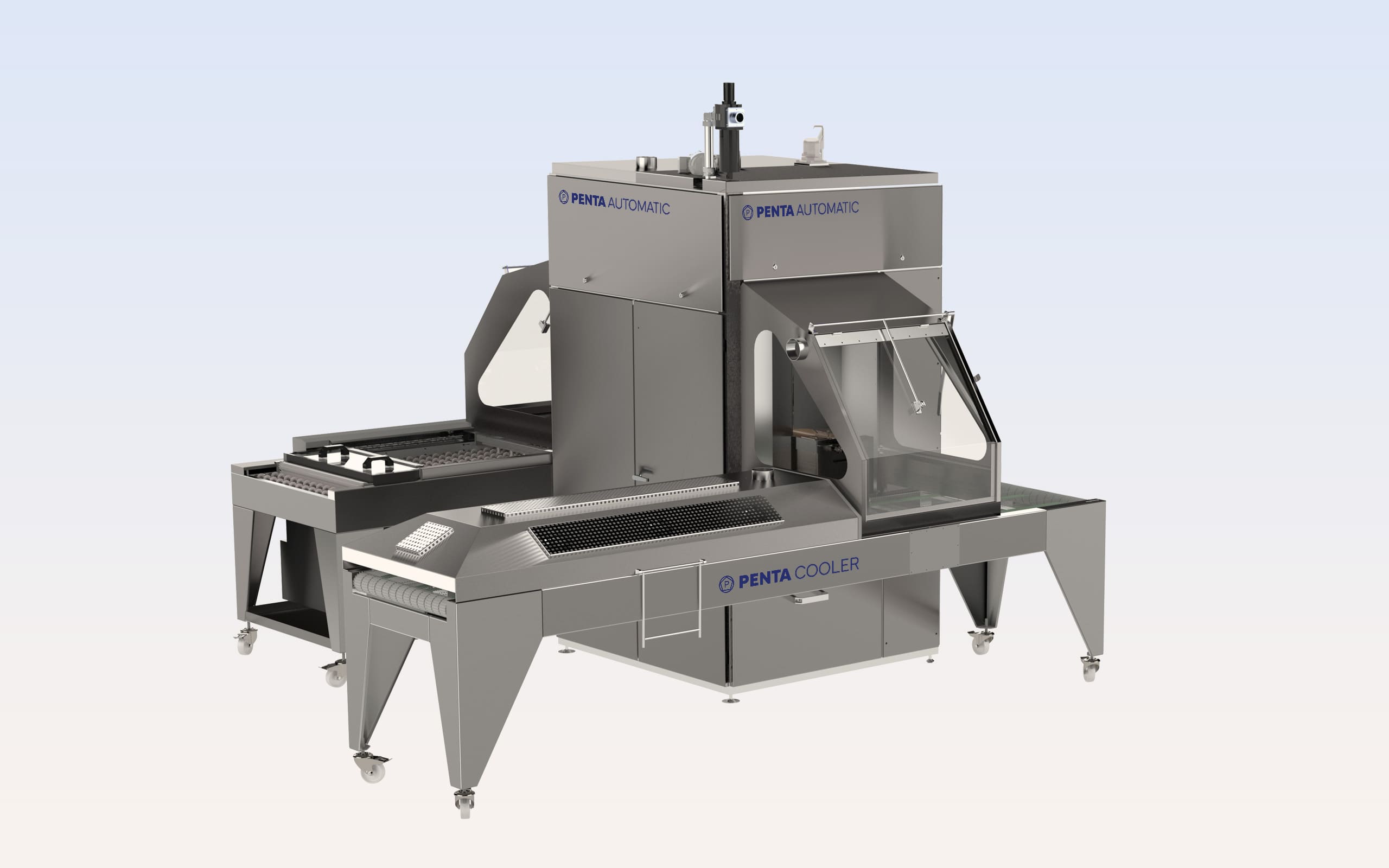

PENTA AUTOMATIC consists of an upstream flux module, the main automatic HASL module and a downstream cooling section. The employee in charge only has to operate the stackers and unstackers of the line. PENTA AUTOMATIC requires insignificantly more valuable production space than a conventional manually operated tinning line. The availability is approx. 95 %, i.e. with an operation of 24 hours, only approx. one hour of maintenance time has to be included. The spare parts requirement per year amounts to only a few hundred euros. The low costs for spare parts and the low susceptibility to malfunctions as well as the low maintenance times and the space savings result in extremely low operating costs. Another advantage of the vertical fully automatic machine is the lower consumption of fluxing agents and the elimination of cover oils, which are expensive to dispose of. The built-in horizontal fluxer requires only 50g / m2 of flux. This means that, in contrast to other fully automatic Hot air Leveling systems, only one third of the flux is consumed.

Features

Technical features

Air heater (connected load): 19.2 KW

Solder pot (connected load): 34.4 K

Other consumers incl. inlet and outlet conveyors

(connected load): 4 KWAir

consumption: 18 KW (compressor power)

Suction: 2800 cbm/h at 800 - 1000 PA suction power

Air connection: R 1 1/2

Compressed air line cross-section: min. 40 mm

Solder pot filling: 400 kg lead solder / 360 kg lead-free solder

Clamp cross/drive: regulated three-phase motor

Lift/toothed belt drive: regulated three-phase motor

Travel speed variably adjustable in user menu

Loading arm/drive: pneumatic cylinder

Unloading arm/drive: regulated three-phase motor

Pump drive: regulated three-phase motor

PENTAGAL

Chemie und Maschinenbau GmbH

Carolinenglückstraße 35

44793 Bochum / Germany

Phone: +49 234 / 52 32 37

Fax: +49 234 / 52 29 89